A lens is a transparent optical element bounded by two surfaces, at least one of which has curvature. Lenses change the direction of light rays through refraction, focusing or dispersing light. They form the basis for vision correction, image formation, and light control in optical systems.

Materials and technologies

It is possible to manufacture lenses from the catalogs “Colorless Optical Glass” 13659-78, “Quartz Optical Glass” 15130-86, as well as OXARA, Schott, and other available materials upon customer request.

Main properties and functions of optical lenses:

- Refraction of light – a lens changes the direction of rays due to its curved surface (convex, concave, or combined).

- Focusing or dispersing: Diverging (negative) lenses (concave) — used for correcting myopia (nearsightedness). They reduce the optical power of the eye, directing the image onto the retina.Converging (positive) lenses (convex) — used for hyperopia (farsightedness). They increase optical power for proper image focusing, i.e., they focus light into a point.

- Image formation. Lenses can create real or virtual images, enlarge or reduce them.

Applications

- Photo and video equipment (camera lenses, microscopes, telescopes, etc.)

- Laser systems (beam focusing)

- Medicine (endoscopes, optical sensors)

- Industry (measuring instruments, scanners)

Whatever your application, we have a suitable spherical lens to meet your requirements.

| Specification | Standard | Achievable |

|---|---|---|

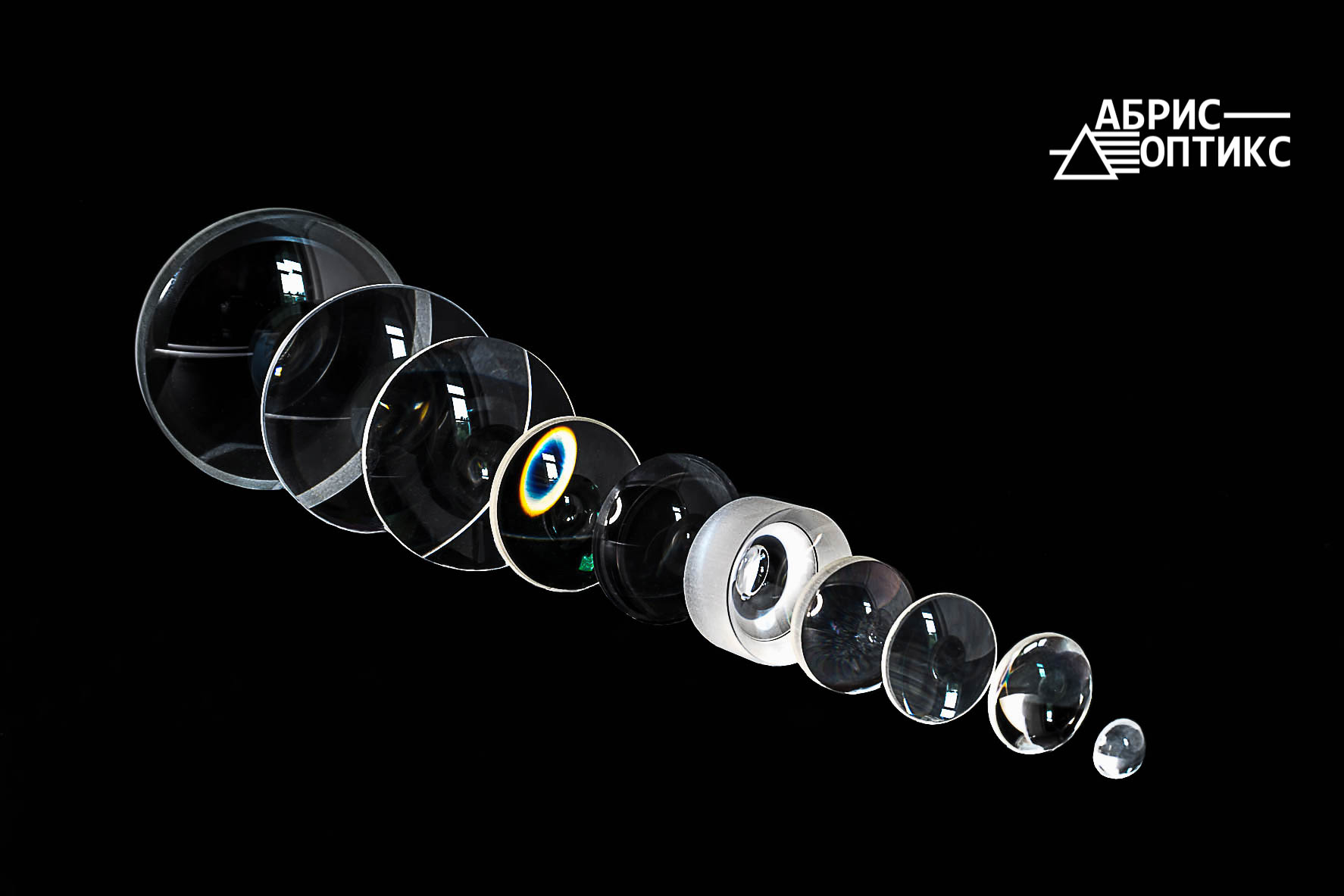

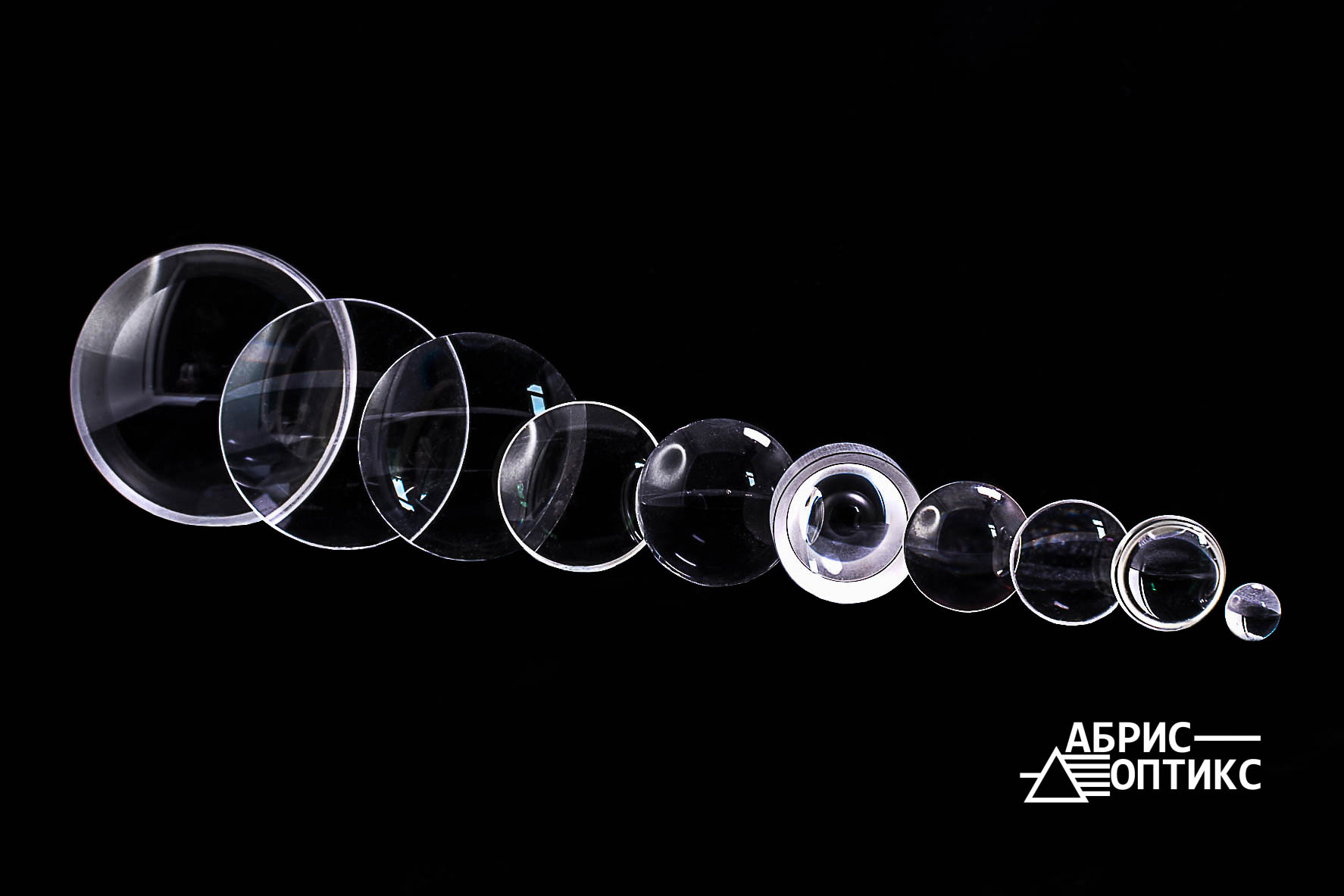

| Lens shape | Round, rectangular spherical, ball-shaped | As per customer request |

| Lens type | Plano-convex, plano-concave, biconvex, biconcave, positive meniscus, negative meniscus | As per customer request |

| Diameter | 5 – 35 mm | 1.5 – 250 mm |

| Material | “Colorless Optical Glass” 13659-78, “Quartz Optical Glass” 15130-86 | “Colorless Optical Glass” 13659-78, “Quartz Optical Glass” 15130-86, as well as OXARA and Schott |

| Diameter/size tolerance | +0.0/-0.2 mm | +0.0/-0.02 mm |

| Thickness tolerance | +/-0.2 mm | +/0.01 mm |

| Centration | < 0.2 mm | < 0.05 mm |

| Surface quality | P = I – IX | P = 0 – 10, 0 – 20, 0 – 40, I – V |

| Local defect (at 633 nm) | 0.5 fringe | 0.2 fringe |

| Focal length tolerance | +/-2% | +/-0.05% |

| Clear aperture | >90% of diameter | >95% of diameter |

| Coating | As per customer request | As per customer request |

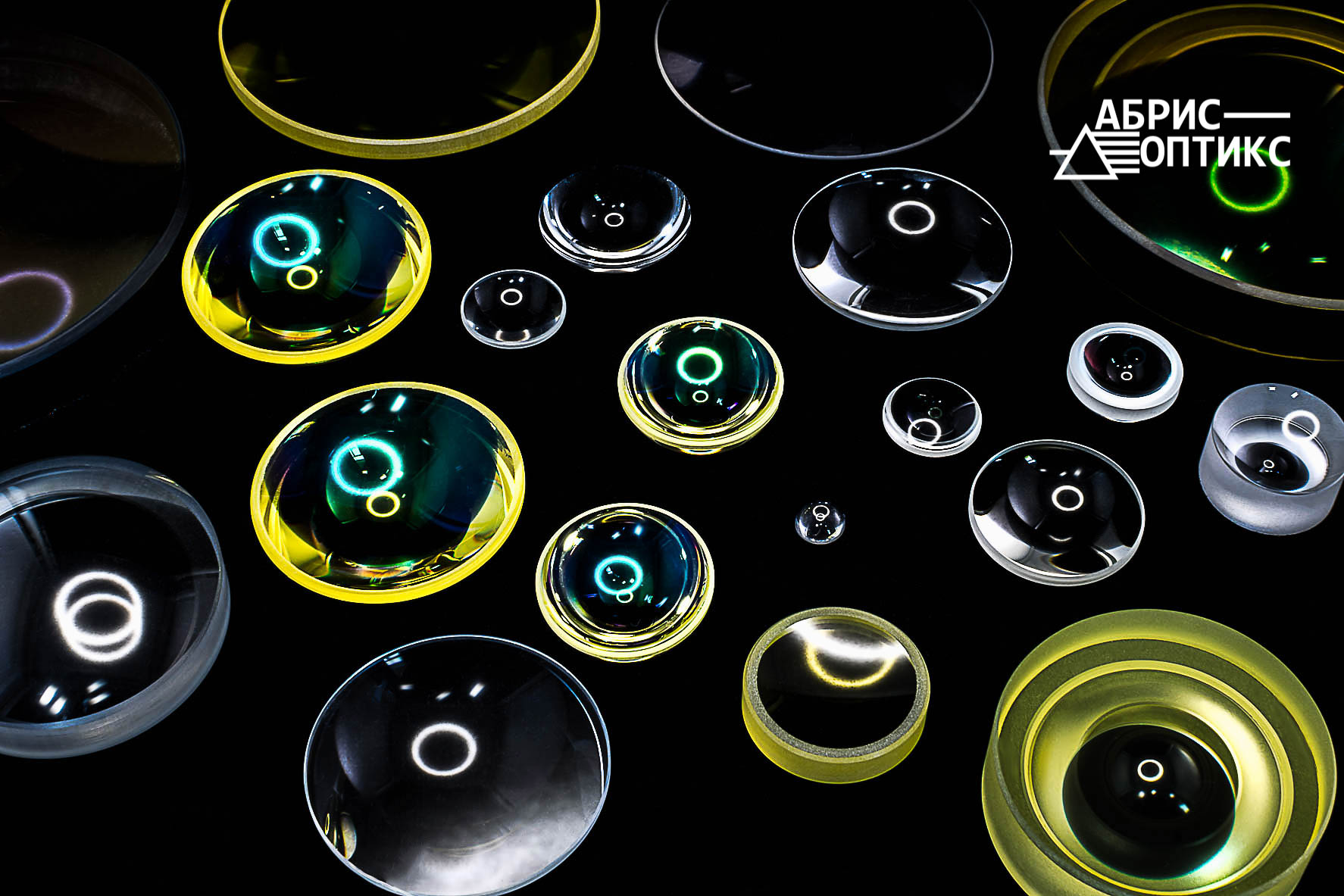

Some examples of spherical lenses we produce:

Plano-convex lenses are optical elements with one flat surface and one convex surface. Such a lens collects incoming light, focusing it to a point, and has a positive focal length. They are widely used in optical systems such as telescopes, collimators, condensers, and various instruments where precise focusing or collimation of a light beam is required.

A spherical collimating lens is an optical element with a simple spherical surface, used to transform a light beam into a parallel one. They are successfully used in laser systems, fiber optics, and scientific instruments for light collimation.

Advantages of ordering spherical optics from our company:

- High quality and precision. We manufacture lenses with minimal deviations from specified parameters (λ/4, λ/10 and higher). Precision grinding and polishing equipment ensures perfect surface sphericity.

- Wide choice of materials.

- Custom parameters. Any radii of curvature, diameters, thicknesses, and shapes (biconvex, plano-concave, etc.). Possibility of manufacturing according to your drawings or technical specifications.

- Optical coatings. Antireflective, reflective, protective, and more. Application of multilayer coatings for specific wavelength ranges.

- Standards compliance. Quality control according to GOST (interferometry, spectrophotometry).

- Competitive prices and flexible terms. Optimized production allows us to offer favorable prices without loss of quality. We work with both small and large batches (from single pieces to serial production).

- Fast manufacturing times. In-house production and logistics reduce order lead time.

- Technical support. Assistance in material selection, optical parameter calculation, and lens design, including selection of glass according to catalogs.

- Additional processing. Edge rounding and application of light-absorbing paint on the end surface (painting with HS-75GM or HS-543).

- Reliability and guarantees. Each lens undergoes strict inspection before shipment. Upon request, we provide accompanying documentation (passports, certificates).